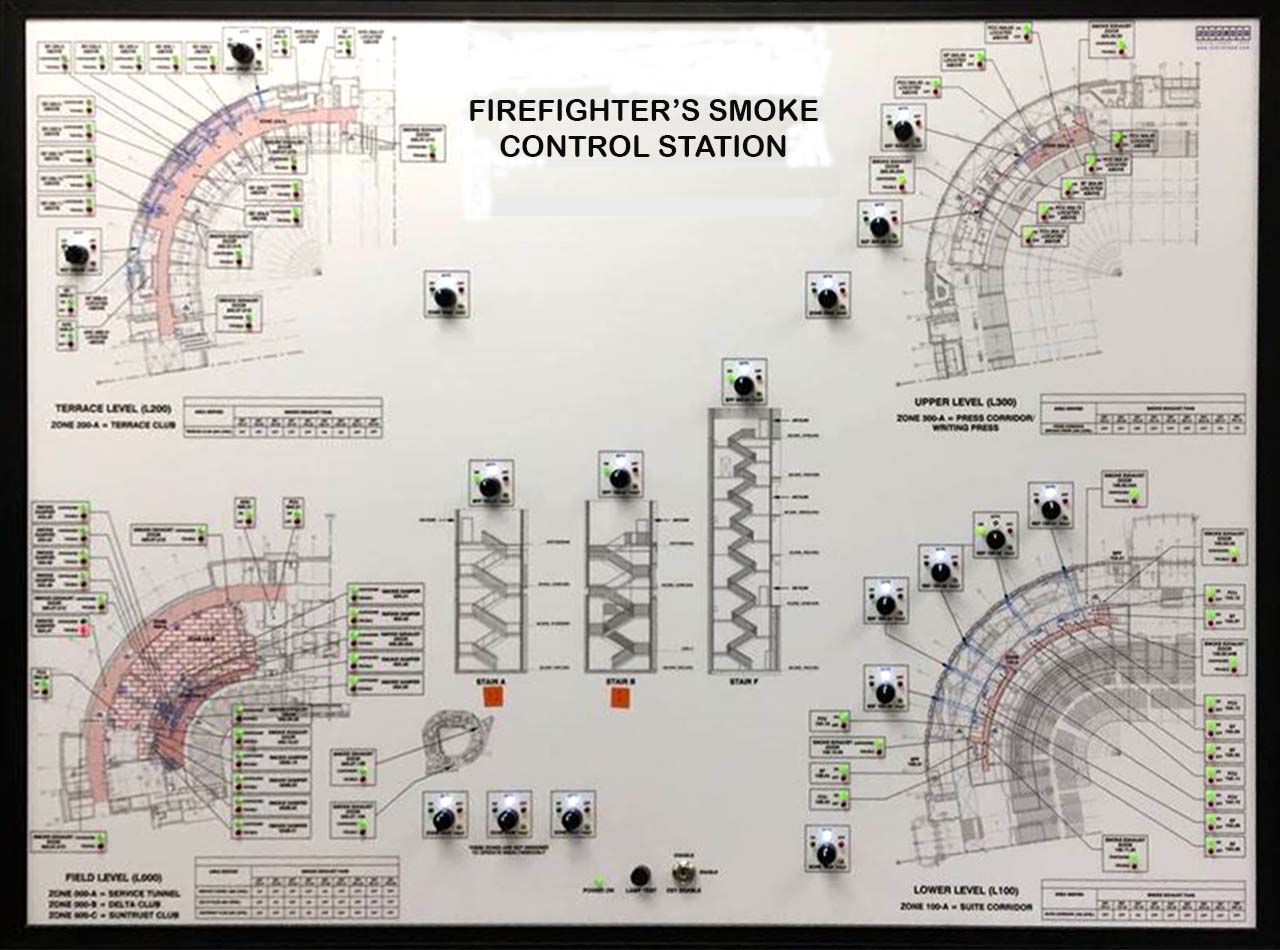

Smoke Control Special Inspections

Even the most robust smoke control system designs become ineffective when components are not installed correctly, do not operate properly, or lack appropriate integration. CCI’s special inspections process leverages our extensive smoke control systems knowledge to effectively test and inspect systems and ensure the owner receives the life safety system outlined in the construction documents.

Whether addressing construction issues, reviewing design documents for compliance with the required rational analysis, or establishing systems testing requirements, the goal is to minimize changes during construction and eliminate delays in approval.

In addition, CCI can be a resource for facility managers during yearly smoke control maintenance and operation testing.

Firestop Systems Special Inspections

CCI’s firestop experts conduct special inspections of firestop systems to ensure compliance with the International Building Code. CCI firestop inspectors are specially trained, have successfully completed the UL Firestop Exam, and are certified by the International Firestop Council. CCI does not install firestop systems or manufacture firestop products, and thus functions solely as an independent inspection agency.

CCI firestop inspectors are certified by the International Firestop Council (IFC), which is described by the IFC as the most direct indication and proof that the level of knowledge of firestop installation is of the highest caliber. This, in combination with training from installers and manufacturers, provides CCI special inspectors with the knowledge and expertise necessary to perform firestop system reviews and inspections.

Fire Door Inspections

CCI’s fire door experts conduct inspections of fire door assemblies to ensure compliance with NFPA 80, Standard for Fire Doors and Other Opening Protectives. CCI fire door inspectors are trained through the International Fire Door Inspection Association (IFDIA) and by licensed CCI Fire Protection Engineers. Whether you are seeking inspection and maintenance compliance with the International Fire Code or are a health care facility where the annual fire door inspection is mandated, CCI has the specially trained and highly qualified inspectors to support your compliance.

CCI is a member of the NFPA 80 Technical Committee and is directly involved in the development of the requirements for fire doors and other opening protectives, including the inspection requirements. This combined with our training and comprehensive fire protection and life safety knowledge gives CCI the expertise necessary to perform fire door inspections.

Fire Sprinkler Corrosion Assessment

CCI offers Fire Sprinkler Corrosion Assessment of existing systems to determine the extent of corrosion damage on the internal pipe walls in fire sprinkler systems. The program incorporates processes to determine the root cause of corrosion and the severity of damage. Recommendations are provided to remediate existing corrosion, and reduce future corrosion. In many cases it is not necessary for the entire fire sprinkler system to be replaced. Remediation of the system with limited pipe replacement and the implementation of a comprehensive corrosion control strategy can “save” many systems.

Services:

- Consultation for new systems and strategies for limiting corrosion

- Review of existing system “as-built” drawings

- Performing internal piping video inspections

- Coordination of sectioning, cleaning, and analyzing pipe samples

- Identification of “hot spots” within the system where failures have occurred

- Identification of most likely locations for accelerated rates of corrosion

- Defining “root causes” of corrosion

- Determining the type and degree of microbial contamination

- Determining the elemental composition of collected debris

- Identifying and developing cost effective solutions for existing systems

- Corrosion control strategy development and recommendations